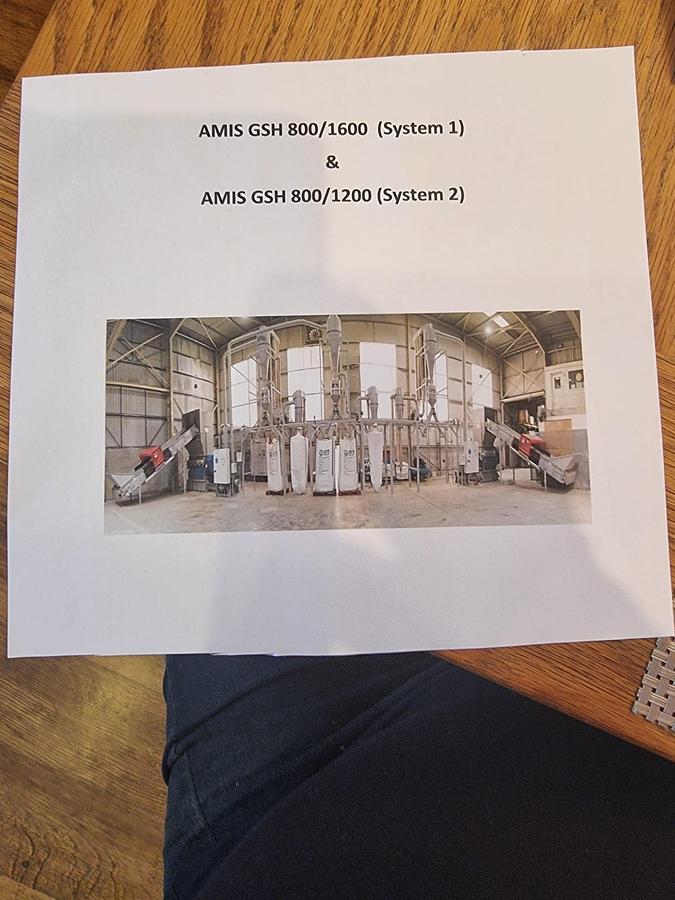

2022 Amis GSH 800/1200 Plastics Granulator Plant

Description

Amis GSH 800/1200 Plastics Granulator Plant. Immediate availability.

- Year: 2022

Plant consisting of:

Hopper; Conveyor feed hopper equipped with curtains to prevent fly back.

Hopper can be lifted together with the hinged upper housing part hydraulically.

Therefore the rotor is easy acceptable for maintenance and cleaning

Rotor; Open 7 row type rotor in welded steel construction with 7 x 2 rotating knives angled in slanted form to give an X type cross cut action. Extended rotor shaft for mounting of flywheel. Pre-adjustable rotor knives for minimum downtime at knife change.

Rotor bearings; Bearings with external outboard steel bearing housings. Rotor weld beaded with wear resistant surface.

Knife setting jig; Fixture supplied with the machine for quick adjustment of the knives outside the machine. Minimizes downtime and makes knives change easier.

Housing design; Centrally hinged two piece welded steel construction, creating a "clam shell' design. 3rd stator knife is mounted at the backside of the upper housing part which reduces the aggressiveness of the machine and allows the grinding of thick walled materials and lumps. Replacable wear plates on the sides of cutting chamber walls.

Upper housing access; The upper housing is easily opened by means of electrically energized hydraulic assembly. This allows for quick access during knife replacement or screen removal.

Screen mounts; The screen is located in a hinged support and is removed hydraulically through the inspection door in the lower section of the housing.

Base frame; The granulator, complete with the drive motor (on tension rails) with pulleys and V - belt casing is mounted on a flat frame. The frame is supplied with anti-vibration pads.

Pulleys; Oversized to cope with peak loads that may occur. The granulator pulley is designed as a fly wheel. Auxiliary flywheel can be installed on the non-driven side for additional inertia.

Main drive; AC - motor 132 kW three phase motor, type B3, protection IP 54,

400 V, 50 Hz, 1500 rpm, heavy duty bearings.

Safety devices; integrated run down safety devices prevent access to the unit until the rotor has reached a stand still.

Also included: 2 x MFT 55/500 material transport system for discharging the material from the granulator and to transport the material to double Big-Bag station.

This comprises of:

Material transport blower 11,0 kW

Connection pipe work © 200 mm

Cyclone separator © 800 x 2400 mm

Mounting frame for double Big-Bag discharge

Filter hood with 12 hanging filter bags

Pneumatic Big Bag switch with level sensors

Light indicators when BB is full

Fines separator type FAS 600 with 2,2 KW blower single Big-Bag

Electrical control cabinet

To control the entire system

All switch components are incorporated in a sturdy steel plate cabinet. Switches are designed with automatic star-delta protection, press button switched with indicator lights, main switch is lockable, wired to a terminal strip, including fuses.

Designed to the current valid VDE safety regulations.

Cables between the individual components and the panel are not included

Spare part package

- 1 set spare rotor knives = 28 pcs.

- 1 set spare stator knives = 4 pcs.

- 1 set spare block knives = 4 pcs.

- 1 spare screen @ mm upon request

For further information or to arrange a viewing, please get in touch.

Specifications

| Manufacturer | Amis |

| Model | GSH 800/1200 |

| Year | 2022 |

| Condition | Used |